Alejandro Carnero is the Production Manager of Lancer Orthodontics in Mexicali, a global provider of orthodontic products for thousands of orthodontists and dentists worldwide.

Alejandro is a graduate of Culiacan Institute of Technology, School of Engineering.

Lancer designs, manufactures and markets products utilizing three manufacturing systems: Traditional (Casting), Progressive (Metal Injection Molding MIM) and New Individualized Ortho (Patient Specific Customized Appliances).

Established in PIMSA Mexicali since 1997, Lancer manufactures products with a singular commitment to bring a performance advantage to every technology, product and service it provides.

“The fact that we are in Mexico brings attention, negative and positive, but when they see product quality in Mexicali it all turns to positive!” – Alejandro Carnero.

If interested in Lancer capabilities, please email to: erick@pimsa.com.mx

PDF: PIMSA WHOS WHO ALEJANDRO CARNERO

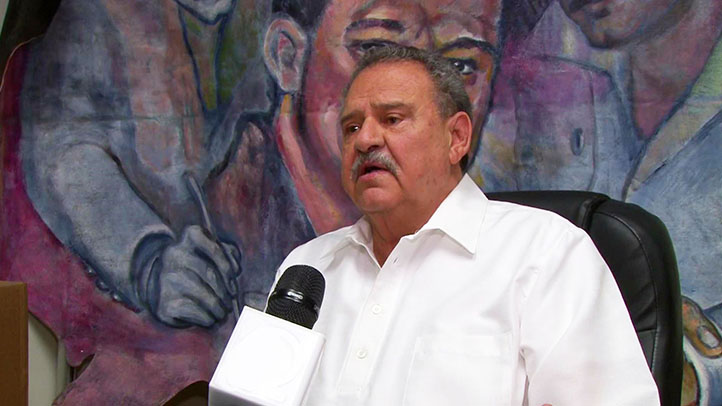

Mexicali, state capital of Baja California, has now a new elected Mayor.

Gustavo is a native of Mexicali, married with Margarita Flores and father of two sons, Gustavo and Alejandro, currently attending university.

He is a graduate of UABC (Baja California State University), School of Law; with a master’s degree in Fiscal Law, by The University of Guadalajara.

Gustavo comes from one of the pioneer families of Mexicali, for years his father ran “Continental Accessories” an auto parts shop in the old downtown.

He has knowledge of Mexicali’s industry, a state legislator with vast experience in working for Mexicali’s Government Administration.

Improving security, better paved roads, creating sports centers, attending issues of transportation for workers, are some challenges that we will be coordinating with our new Mayor.

He takes office this year on December 1st, for a term of three years, with no reelection.

“Mexicali is home of important international manufacturing corporations, I will connect with them to improve their operations in Mexicali. We mean results.”- Gustavo Sanchez, June 2016.

Congratulations Gustavo. PIMSA Companies extend their support for the upcoming administration.

PDF: Congratulations to Gustavo Sanchez, new elected Mayor of Mexicali – PIMSA INDUSTRIAL DEVELOPERS

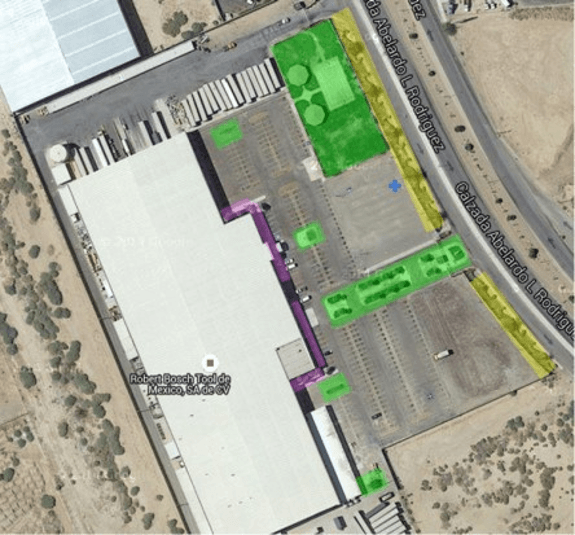

Transformed facility grounds, external garden help conserve water, lower costs.

Mariana Flores Hernandez, facilities coordinator, and a team of fellow associates at Bosch’s Mexicali, Mexico (MexP), location wanted to transform the site’s landscaping to better preserve the natural environment. Located in a dry and hot desert region, the facility was previously covered by large areas of grass and non-native plant species, which required frequent upkeep and high water consumption. To change this, Flores and her team recognized the qualities of their surroundings and focused on cultivating a setting that was better suited to the climate. This resulted in a landscape that was less green, but more authentic to the region and is expected to save more than $25,000 annually on water.

“At MexP, we live and work in a region of the world where water is at a premium,” said Flores. “When consuming water, no matter the purpose or function, we need to closely monitor where and how much of it is being used. Our team realized the way our grounds were previously set up was a drain on valuable resources, specifically water.”

Reducing water use in phases

All of this work to reinvent the MexP location grounds did not happen overnight. The team was looking to do some major renovations, including reconstructing the garden and adjacent shrubbery by using plants native to the desert that thrive in heat and require less water. All this took a series of three phases, beginning in early 2015.

Phase 1 included removing all grass from spaces outside of the facility and installing decorative stone in its place. Phase 2 involved adding desert-compatible plants, some of which include Mezquite, Palo Verde, Texas Sage, Agave Azul and Cola de Zorro, among others, to complement the newly situated decorative stones.

These two phases were completed by mid-2015, allowing the facility to advance into Phase 3, which is expected to be completed in the coming months. In this phase, the final touches are being made to the facility grounds and its external garden. Water lines are being checked, and replaced when needed, and the final collection of flora and rock formations are being set into place.

Throughout this process, MexP has seen steady improvements in reducing water consumption. Once the final phase is completed, the facility expects to reduce water consumption by approximately 7,500 gallons per day and more than 2.8 million gallons per year.

“I commend the hard work that MexP associates have put forth to make a positive impact on their local environment,” said John Young, director, Environmental Health and Safety. “It shows that with some local ingenuity, all Bosch locations can find their own unique ways to improve their sustainability. And even the smallest change can result in big cost savings and improve overall operations.”

Welcome to Mexico, Honorable Roberta Jacobson as new United States Ambassador to Mexico.

Roberta Jacobson, arrived in Mexico City, Mexico Thursday, saying she is excited and confident the two countries will have “excellent communication.”

“I have the intention to travel far and wide in Mexico to get to know the unique attributes of each region and to be able to listen to Mexicans in person,” Jacobson said to the press in Spanish upon her arrival.

Hope we can host your presence in Mexicali, Baja California, an important binational community, with U.S. manufacturing presence; located in the center of a mega region including Arizona, California, Nevada, State of Washington, Sonora, Baja California and Baja California Sur, a market of 63 million people.

We work closely with General Consul William Ostick of the US Consulate General in Tijuana.

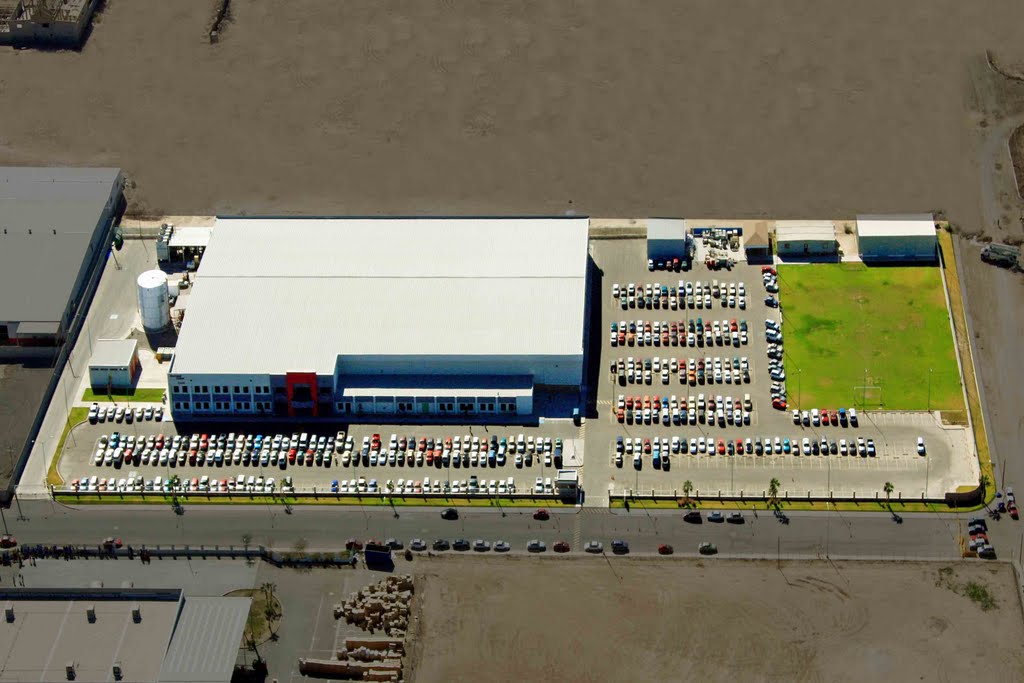

EEMSA, a division of Rockwell Collins Inc., an American multinational company, will be turning 50 this year. It is the oldest maquiladora manufacturer registered in Mexico.

Rockwell Collins is an aerospace company headquartered in Cedar Rapids, Iowa. It designs, produces, and supports communications and aviation systems worldwide.

Its state-of-the-art facility located in PIMSA, Mexicali, Baja California, manufactures communications and entertainment systems for commercial airliners and business and regional jets. With more than 100,000 square feet of production and warehouse space, this facility applies lean principles to cellular production design for optimized workflow.

Operations and manufacturing cells are grouped in families of products to be processed – from component level to final assembly – by the same team. This production process accelerates flow, improves quality and reduces inventory.

In their 50 years, we remember many executives as Amado Avendaño, Javier Gutierrez, Rosalio Valdez among them. Today, managed by Charles Stroo and Ernesto Duarte, EEMSA is a role model of quality, efficiency and a competitive edge in international markets.

The low turnover of EEMSA reflects the on hands human resource management.

“Keep connected to our staff in all areas has been the key to our success” – Ernesto Duarte.

We appreciate Rockwell Collins’ trust through all these years being part of the PIMSA family of companies.

We will join celebration next October, congratulations!

PDF: Rockwell Collins-EEMSA 50th anniversary in Mexicali

Eduardo Martínez Palomera, a visionary man and an important initiator of the maquiladora industry and PIMSA.

Eduardo was born in Mexicali; the Palomera name is synonym of good working families in Mexicali.

A former mayor of Mexicali on two occasions, now retired from PIMSA and dedicated to the community efforts for transparency in government and public services in Mexicali and Baja California.

Eduardo was instrumental in setting up a platform for the development of international companies in Mexico.

“Do it right the first time, but if not, do it again by concentrating on positive results,” one of his mottos.

A PIMSA asset, Eduardo is still very active in assisting young people in Mexicali. Our salute to Eduardo!

Greater Yuma visited PIMSA to explore areas of potential manufacturing capacities that could complement international corporations doing business in Mexicali, with the aim of building business bridges. In picture, Xavier Rivas presents PIMSA’s historical landmark token of Baja California to Julie Engel, President/CEO of Greater Yuma.

Tracy Schultz, a Yuma resident herself and General Manager of Martech, a medical company with over one thousand employees in PIMSA I, also attended this meeting with Greater Yuma Economic Development Corporation in order to support future efforts of collaboration among both regions.

MEXICO CITY — Grupo Bimbo S.A.B. de C.V. is set to enter Africa by the end of 2016, according to El Universal, one of the largest newspapers in Mexico.

Gabino Gomez, executive vice-president of Grupo Bimbo, told participants at an event at Anáhuac University on April 13 that the Mexico City-based baking company sees potential in emerging markets, and Africa fits the bill, according to El Universal. Africa would become the twenty-third market and fourth continent in which Grupo Bimbo has operations.

“I can confirm (to) you that as a leader in the baking industry, Grupo Bimbo is always looking for new opportunities that could arise in any market,” Karina Fogel, a spokesperson for Grupo Bimbo, said in an emailed statement to Milling & Baking News. Ms. Fogel would not confirm that Grupo Bimbo plans to enter Africa or that it plans to do so by the end of this year.

Grupo Bimbo began exporting to the United States in 1984, and in 1994 it entered the United States with the purchase of La Hacienda, a California-based tortilla company. Bimbo Bakeries USA then entered the U.S. bread market in 1997 with the acquisition of Pacific Pride Bakeries of San Diego. The company in 2006 acquired Panrico in Beijing, initiating its presence in the Asian market.

Source: Food Business News

Ensenada, Baja California

Dr. Rafael Chavez (right), President of the Ensenada Chamber of Commerce CANACO, on behalf of PIMSA presenting a historical landmark token of Baja California to Dr. Alonso Vera for his continuous effort to improve and innovate our economic development.

PIMSA is part of Baja California’s economic drive outreaching international manufacturers and recognizing outstanding people like Dr. Vera for attempting to make a difference.

Momentum!

CECATI 84 is a public institution, part of the Secretary of Public Education SEP, dedicated to the development and teaching of technical training courses.

Courses available:

CNC MACHINING

WELDING

ELECTRONICS

AIR CONDITIONING

AUTOMOTIVE MECHANIC

AUTOMOTIVE ELECTRONICS

DIESEL MECHANICS

For more information:

ING. IGNACIO RAMÍREZ

JEFE DEL ÁREA DE VINCULACION

CECATI No. 84

AV. BRASIL Y JAVIER ROJO GOMEZ S/N

COL. ALIANZA PARA LA PRODUCCIÓN

MEXICALI, B.C.,

TEL: 01 686 565-93-70 Y 01 686 565-74-97

Cel. (686) 2710973

www.cecati84.org